Hot Kiln Alignment and Engineering Analysis

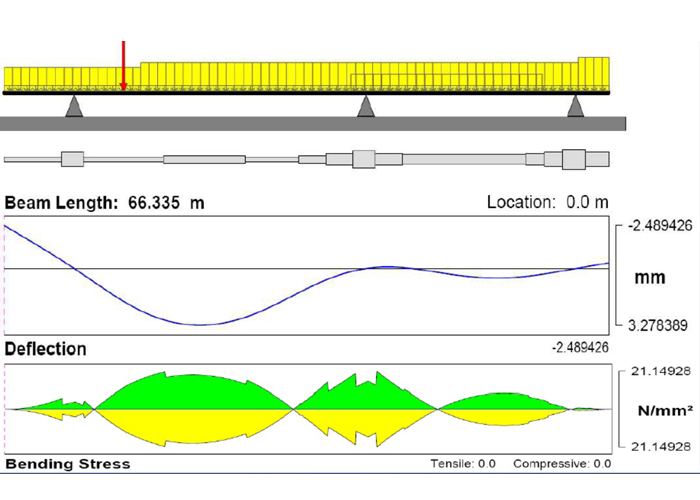

Hot kiln alignment has been with us more than a decade now. The innovation for aligning kilns while in operation brings with it the promise of analyzing its mechanics in a dynamic setting. In doing so, the procedure does not conflict with production or shut down periods.

The unique and modern method by KILN SERVICES PRIVATE LIMITED derives the state of alignment by direct and continuous noncontact measurement to the rotating kiln shell, rather than the usual measurement of diameters and other parameters of the kiln rollers and tires

Also engineering analysis carried out by KSPL based on customer requirement.

Cold Alignment

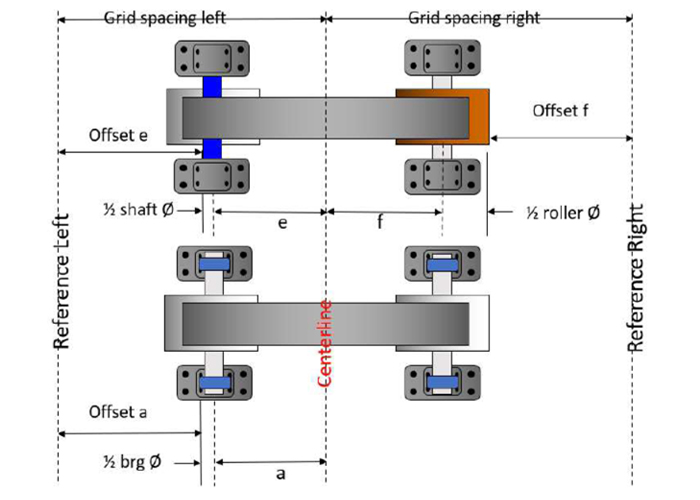

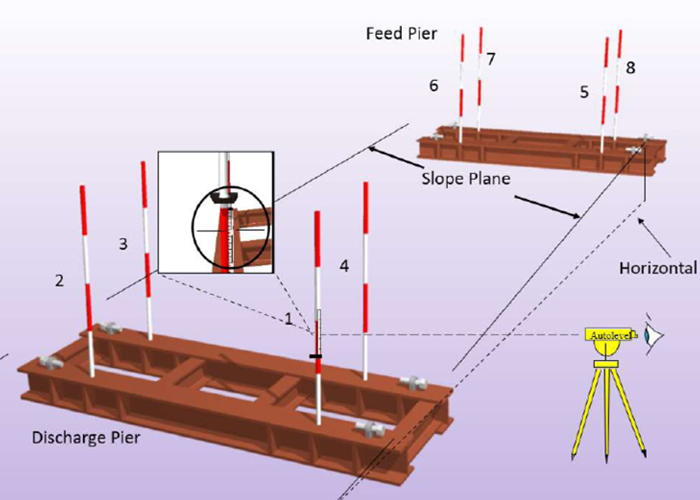

Cold alignment of the Rotary equipment having 2- piers is very critical – as two points will always be in a aligned condition so various parameters mentioned below are measured to determine the actual centerline of the Dryer, Granulator, Cooler, incinerator etc…

- Establish the CENTERLINE.

- The drum should be properly located in the discharge and feed hood (seals).

- Elevation Measurements.

- Off-set Measurements.

- Diameter Measurements.

- Calculations - determining roller positions

- Skew if required

- Girth gear and pinion should be checked for mesh and angular alignment.

Method of Alignment

By establishing reference lines from erected or actual center of the Drum all permeameters of tyre, supporting rollers are measured and using the basic principles of trigonometry cold alignment of stationary drum is carried out.

Ball Mill Inspection

Ball mills are most equipment's of the Cement Industry which are rotating at high speed with heavy mass in it making it more vulnerable to trunnion temperatures and shell cracks

- Checking of Girth Gear axial & radial run out.

- Complete gear & Pinion Inspection.

- Trunnion/ Slide Ring run-out checking.

- Mill Lift at both end.

- Complete UT for Shell, Trunnion & Gear /Pinion.

- Mill Shell Thickness Measurement for any wear.

- Shell Liners inspection.

- Mill Lubrication System Inspection

- Vibration Analysis

- Drive Alignment Check

- Visual Inspection.

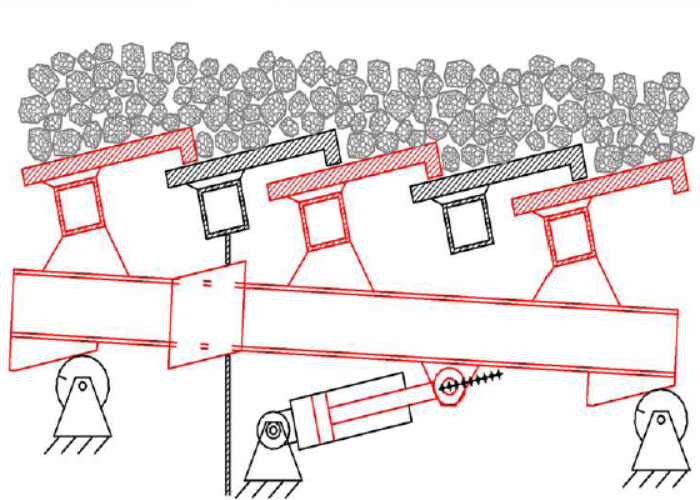

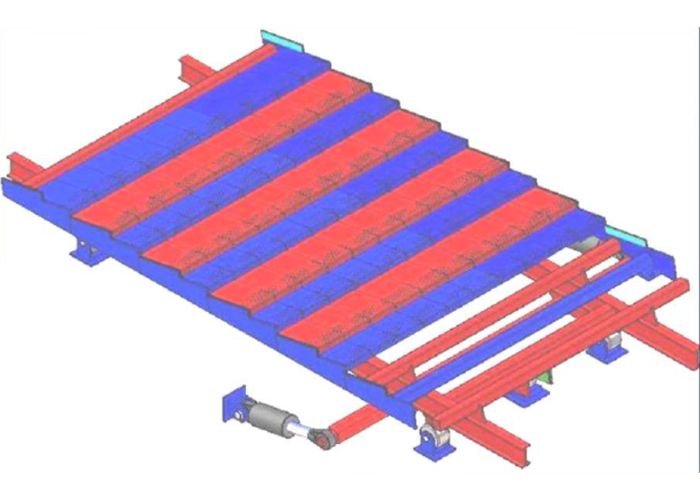

Cement Kiln – Cooler Inspection

By establishing reference lines from erected or actual center of the Drum all permeameters of tyre, supporting rollers are measured and using the basic principles of trigonometry cold alignment of stationary drum is carried out.

- Inspection of cooler and its parts

- Grate cooler alignment

- Parts and drive shaft replacement